Specialist Houston Welding Inspection: Making Certain Structural Integrity and Safety

Wiki Article

The Crucial Function of Welding Inspection: Comprehending the Treatments, Tools, and Standards That Govern Top Quality Assessment in Welding Workflow

Welding inspection is an essential component of quality control in welding procedures, making sure the architectural integrity and security of bonded settings up. By utilizing a series of procedures, from pre-weld assessments to sophisticated non-destructive screening methods, assessors systematically assess weld high quality against strict sector criteria. The tools utilized in these procedures is critical for identifying prospective imperfections that might endanger efficiency. Recognizing the interplay in between inspection methods and governing conformity increases vital questions concerning the challenges faced in keeping these necessary protocols. What effects do these elements have on the overall efficiency of welding operations?Relevance of Welding Inspection

Welding evaluation is critical in ensuring the honesty and safety and security of bonded frameworks, as it regularly serves as the last checkpoint prior to parts are taken into solution. The value of this examination depends on its capacity to determine potential flaws that may endanger the efficiency and durability of bonded joints. Given the high risks entailed, especially in sectors such as building and construction, aerospace, and auto, detailed inspection processes are vital.Welding defects can occur from various variables, consisting of improper techniques, inadequate tools, or inappropriate products. Failure to discover these issues can bring about catastrophic repercussions, including structural failures, which may cause injury, death, and substantial monetary responsibilities. Welding inspection gives an organized technique to examine the high quality of welds, making certain conformity with market requirements and governing needs.

In addition, effective welding assessment adds to improving general productivity by lessening rework and guaranteeing that tasks continue to be on time. By promoting a society of quality control, companies can likewise increase their reputation and client trust. Basically, the value of welding assessment can not be overstated, as it plays an essential function in safeguarding both human lives and financial investments in infrastructure.

Trick Examination Treatments

A thorough technique to evaluation procedures is crucial for making certain the top quality and integrity of bonded joints. Efficient evaluation starts with pre-weld analyses, which include evaluating welding requirements, material buildings, and joint layouts to determine potential difficulties. This preparation phase establishes a standard for quality assumptions.

Throughout the welding process, in-process assessments are critical. Assessors keep an eye on criteria such as heat input, traveling speed, and electrode angle to ensure conformity with recognized requirements. Aesthetic assessments are the first line of protection, allowing the identification of surface area problems, such as splits, porosity, or incomplete fusion.

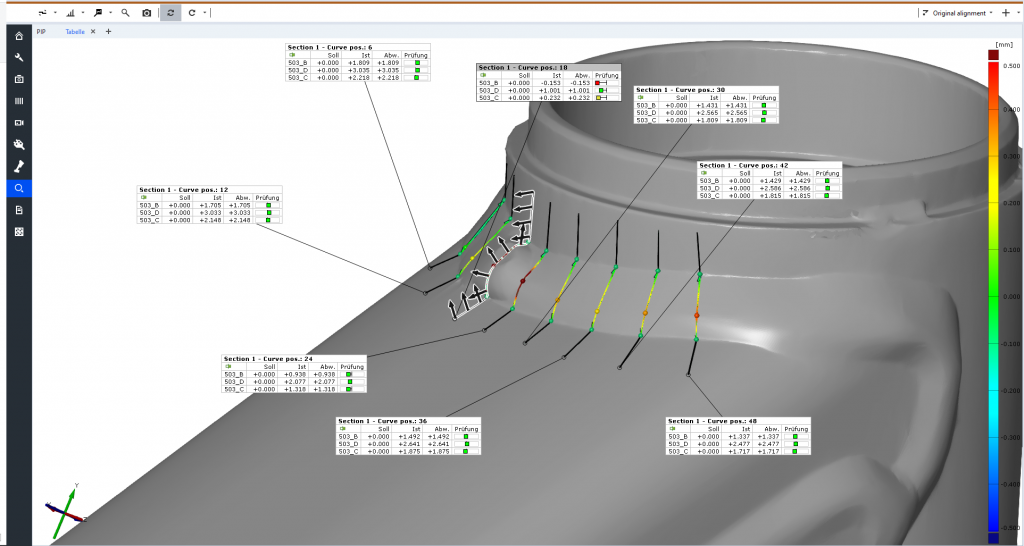

Post-weld inspections involve more sophisticated techniques to analyze the stability of the joint. This may consist of non-destructive screening (NDT) techniques such as ultrasonic screening, radiographic screening, or magnetic particle screening. These methods offer much deeper insights right into the internal structure of the weld, disclosing possible flaws that may not show up on the surface.

Paperwork plays an integral role throughout the inspection procedure. Detailed records of examinations, consisting of searchings for and corrective activities, guarantee traceability and responsibility, inevitably adding to continuous improvement in welding practices and overall top quality assurance.

Necessary Equipment for Evaluation

Efficient examination relies on using specific tools developed to evaluate the top quality and integrity of welded joints. Secret tools in this process consist of visual examination tools, such as amplifying borescopes and glasses, which allow assessors to recognize surface area issues and irregularities. In addition, ultrasonic testing (UT) devices plays a crucial duty by making use of high-frequency sound waves to detect internal flaws within welds, making certain that concealed weak points are recognized prior to they lead to failing.Radiographic screening (RT) is an additional important technique, using X-rays or gamma rays to create images of the welds, exposing interior defects that may not show up through other evaluation approaches - Houston Welding Inspection. Magnetic particle testing (MT) is used for ferromagnetic products, permitting inspectors to locate surface area and near-surface issues by using magnetic areas and fine particles

Dye penetrant testing (PT) is also significant, entailing the application of a fluorescent dye blog to disclose surface cracks and interruptions. Each of these techniques and tools adds to a thorough evaluation strategy, making sure that welded structures satisfy the needed top quality standards and remain risk-free for usage in their respective applications.

Industry Standards and Rules

Quality assurance in welding assessment is significantly affected by sector criteria and laws that control methods and make certain safety. These criteria act as benchmarks for high quality, detailing the essential protocols for documentation, screening, and evaluation. Secret organizations such as the American Welding Culture (AWS), the American Society of Mechanical Designers (ASME), and the International Organization for Standardization (ISO) develop standards that welding experts should follow throughout the evaluation procedure.Compliance with these standards is not just an issue of regulatory responsibility but likewise an important component of risk management in welding procedures. They encompass numerous elements, including product selection, welding methods, and qualifications of workers. As an example, AWS D1.1 lays out architectural welding needs, while ISO 3834 defines top quality requirements for welding he said processes.

Furthermore, industry laws dictate the necessary credentials for welding examiners, requiring certifications that verify their knowledge. This positioning with standards guarantees that evaluations are performed continually and properly, ultimately securing the integrity of welded structures. Following these sector criteria and policies is paramount in promoting operational efficiency and maintaining public rely on welding methods.

Obstacles in Welding Evaluation

Welding inspection deals with many difficulties that can impact the reliability and security of bonded structures. One considerable obstacle is the complexity of the welding processes themselves, which can differ greatly depending upon materials, joint arrangements, and ecological problems. This variability demands a detailed understanding of diverse evaluation methods and their appropriate applications.

An additional difficulty hinges on the progressing nature of welding technology. As new products and methods are introduced, assessors need to continually upgrade their expertise and skills to efficiently examine the high quality of welds. In addition, the physical availability of weld locations can impede assessment initiatives, specifically in restricted or high-risk view publisher site atmospheres.

Moreover, human factors play an essential role in welding inspection. Houston Welding Inspection. The subjective nature of visual evaluations can lead to incongruities, as various inspectors might interpret the very same weld in a different way. This emphasizes the relevance of standardized training and qualification for examiners to guarantee an uniform strategy to high quality analysis

Finally, the assimilation of innovative innovations, such as automated inspections and expert system, offers both challenges and chances. While these modern technologies can enhance precision and effectiveness, they likewise call for substantial financial investment and competence to carry out successfully. Addressing these challenges is vital for maintaining the honesty of bonded frameworks.

Conclusion

Welding evaluation is important for ensuring the security and integrity of bonded structures. Eventually, a durable welding inspection framework not only assures compliance with laws however likewise enhances overall functional effectiveness and integrity. Houston Welding Inspection.Welding assessment is an important component of top quality guarantee in welding procedures, making certain the architectural stability and safety and security of bonded settings up.Welding inspection is crucial in making sure the stability and security of welded frameworks, as it frequently offers as the final checkpoint before components are put into service. Welding assessment gives a systematic technique to evaluate the high quality of welds, ensuring compliance with industry criteria and regulatory requirements.

Quality assurance in welding assessment is considerably affected by industry standards and regulations that govern techniques and make sure safety and security. Key companies such as the American Welding Culture (AWS), the American Society of Mechanical Designers (ASME), and the International Company for Standardization (ISO) develop standards that welding professionals need to adhere to throughout the examination procedure.

Report this wiki page